- Solutions

-

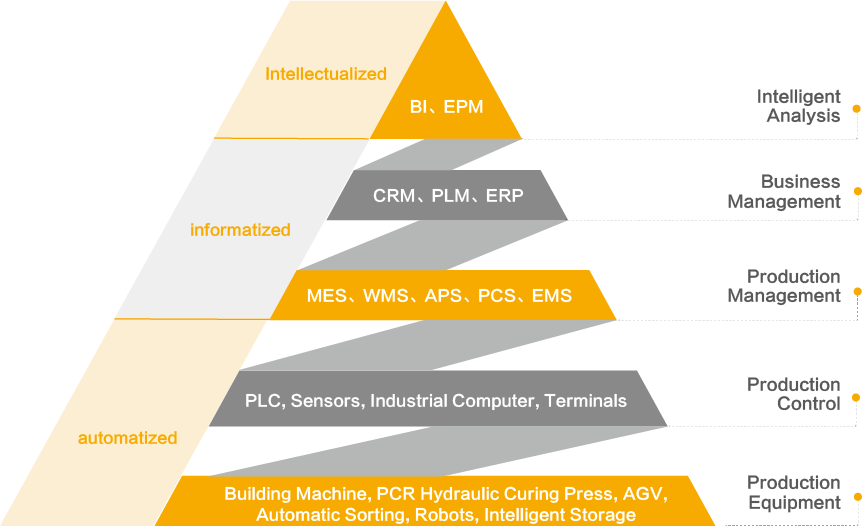

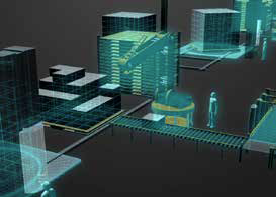

Safe-Run smart factory solutions are grounded in industry networking, logistics automation, smart machinery, equipment communication,

systems data real-time collection, intelligent analysis and other advanced technologies. Safe-Run introduces information and

communication technology to the entire manufacturing process, covering the tire production process - from materials storage,

through mixing, building, curing, testing, to the finished product. Automation of the production process and intelligent

management contributes to the creation of smart factories.

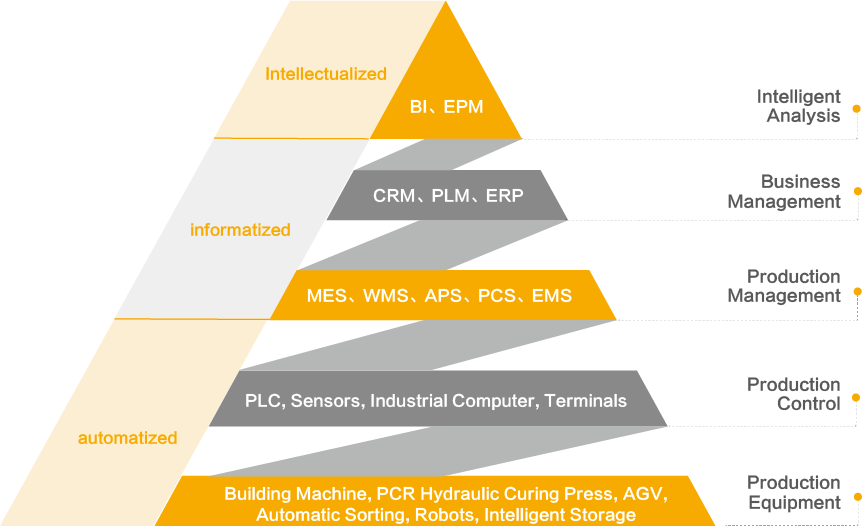

- Simulation, risk reduction,

and optimal design

- Production lines, equipment and processing are analysed and modelled in detail. The derived modelling data allows

for comparison of smart factory data,predictions of outcome, and verification of prediction, risk reduction, and

ensured optimization of the smart factory design.

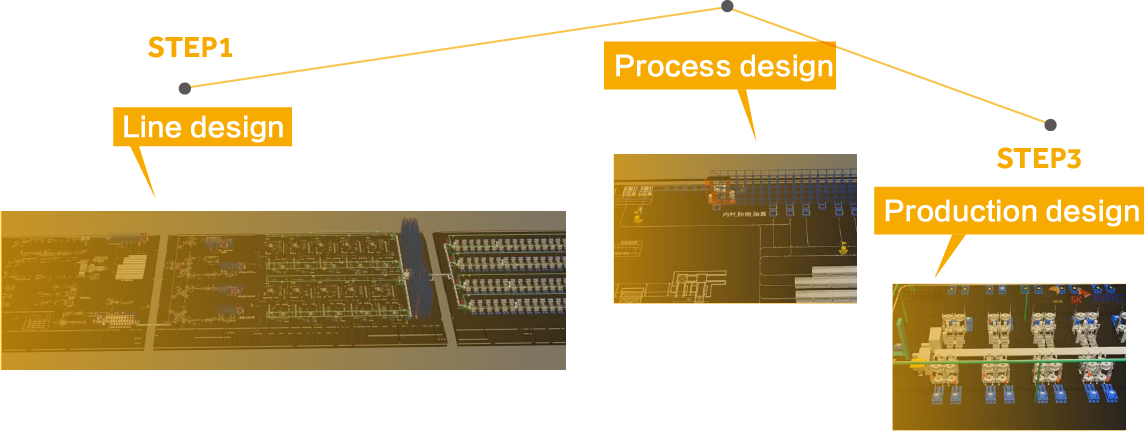

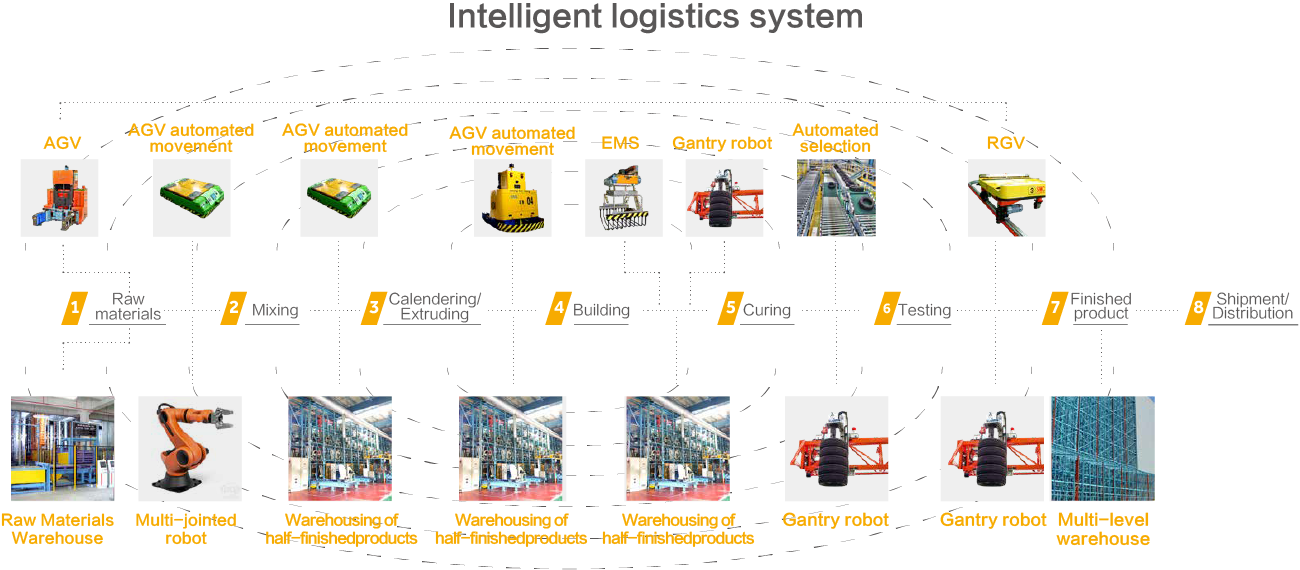

- Logistics optimization and

intelligent warehousing

-

Real-time mobile data and production line information allows for integrated advanced intelligent algorithms and industrial control

technology. This shows and controls smart logistics machinery and automated warehousing, so as to establish automated and unmanned operations.

Intelligent automated storage for access to the warehouse, dynamic storage planning and visual monitoring together allow for intelligent

management which in turn creates more than ten times the storage space.

- Information trace management,

responsiveness to changes in the production environment

- IOT, data, and cloud technology organically connect the IT and OT environments; collecting and analyzing real-time data;

adapting to changes in the production environment; maintaining an optimized production environment and production efficiency; so as to manufacture

individualized products, and adapt to changes in the manufacturing environment for complete smart innovation.

- Integrated visual technology

applications, and real-time

intelligent monitoring and

management of the

whole production line

- Integrated CCTV, face recognition devices, sensory devices all work to provide production site visibility. Through visual

analysis and production line control and the use of an integrated data link system, all production lines undergo real-time

monitoring, so that abnormalities in the production lines can be immediately resolved.

Managers of the production plan and site can smart-manage and optimise the production process;

Optimized algorithms allow established schedule planning, and advance process planning creates KPI. Automatic

prioritisationoccurs according to the situation.